Installation &Maintenance

Installation &Maintenance1. Installation Guidelines

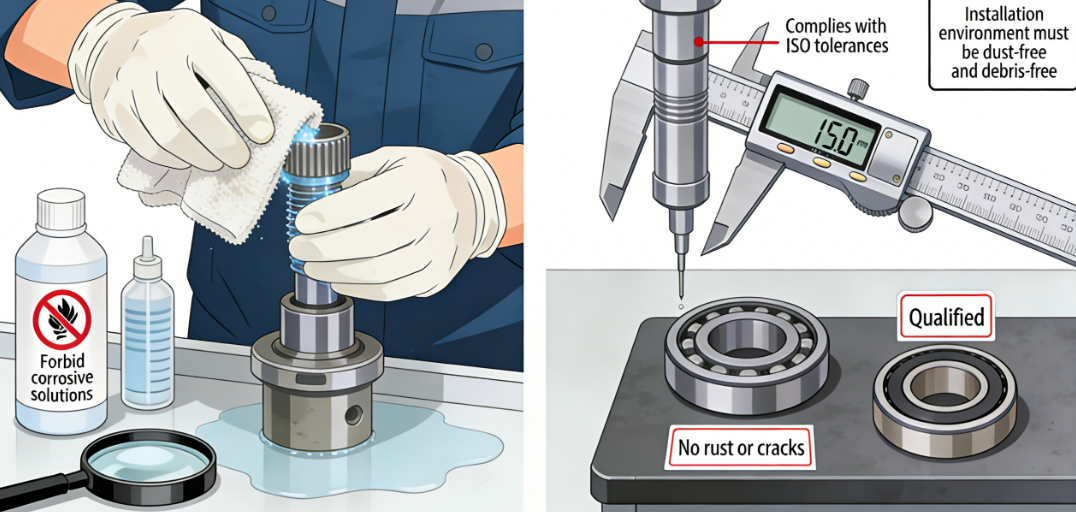

● Cleanliness Check: Ensure the installation environment, shaft, housing, and related components are free of dust, debris, and grease residues. Contaminants can cause premature wear, noise, or seizure of bearings. Use lint-free cloths and appropriate cleaning agents (avoid corrosive solutions) to wipe all mating surfaces.

● Component Inspection: Verify that the shaft and housing bores meet dimensional and geometric tolerances (consistent with ISO, DIN, or specified standards). Check for burrs, scratches, or deformations—any irregularities should be smoothed or corrected before installation. Confirm the bearing model, specification, and surface condition (no rust, cracks, or damage) matches the application requirements.

● Tool Preparation: Use professional installation tools (e.g., hydraulic presses, sleeve tools, torque wrenches) to avoid direct hammering or impact on the bearing ring. Improper tools can damage the bearing’s internal structure, affect rotational accuracy, and reduce service life.

● Lubrication Preparation: Select the appropriate lubricant (grease or oil) based on the bearing type, operating temperature, speed, and load conditions. Ensure the lubricant is compatible with the bearing material and meets industrial standards. Pre-lubricate the bearing and mating surfaces lightly to reduce friction during installation.

2. Maintenance & Care

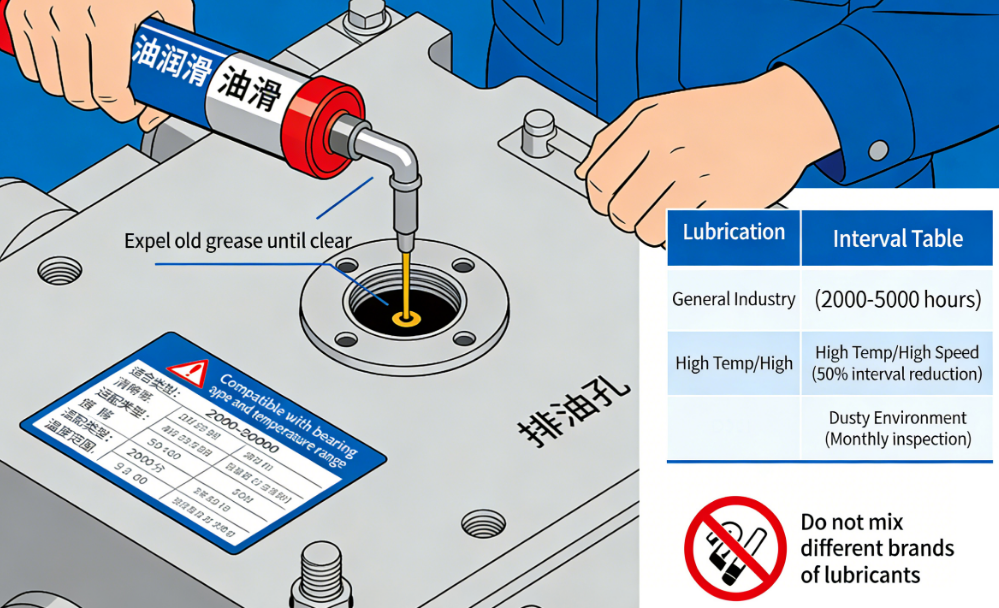

● Lubrication Interval: Depending on operating conditions (speed, temperature, load, and environment), establish a regular lubrication schedule. For general industrial applications, relubricate every 2,000-5,000 operating hours; in high-temperature, high-speed, or dusty environments, shorten the interval appropriately.

● Lubrication Method: For grease-lubricated bearings, use a grease gun to inject new grease through the lubrication hole until old grease is expelled from the relief hole (ensuring complete replacement). For oil-lubricated bearings, check the oil level regularly and replace the oil every 3-6 months.

● Lubricant Replacement: When replacing lubricant, clean the bearing and lubrication system thoroughly to remove residual old grease/oil and contaminants. Avoid mixing different types or brands of lubricants to prevent chemical reactions that degrade lubrication performance.

Wanyang Bearing: Power Your Value.Boost Your Project's Efficiency & Reliability. Connect with Wanyang Today.